| |

|

XJ新(xīn)式漿液泵 |

| 流量範圍:15~2500m3/h |

| 揚程範圍: 5~60m |

| 介質濃度:≤60% |

| 介質溫度:≤100℃ |

| 用於濃度6%粗、細、漂白紙漿輸(shū)送,也適用於堿回收苛化工段(duàn)(沉渣、濾液、乳液)輸送、也(yě)適用纖維長度30~40mm棉漿(jiāng)、化學漿(jiāng)的輸送。 |

谘詢熱線:13801427722 13952608395 谘詢熱線:13801427722 13952608395 |

|

| |

| 詳細(xì)介紹 |

| 概 述 |

| XJ新式漿液泵是臥式、單級、單吸離心泵,吸收國內外同類產(chǎn)品的先進技術,精心研(yán)製的新一代係列漿液泵,符合現代(dài)行業高效、節能、運行可靠、無故障、時間長、無泄漏、維修方便等要求。 |

| 用 途 |

可用作石灰石漿(jiāng)液輸送泵(bèng)、石膏(gāo)液排出泵、過濾(lǜ)器給料泵、吸收塔(tǎ)循(xún)環泵、回收泵等。

用於濃度6%粗、細(xì)、漂白紙漿輸送,也適用於堿回收苛化工段(沉渣、濾液、乳液(yè))輸送、也適(shì)用纖維長度30~40mm棉漿、化(huà)學漿的輸送。 |

| 型號說(shuō)明 |

XJ65-200 XJ —— 表(biǎo)示新式漿液泵

65 —— 表(biǎo)示泵出口直徑(mm)

200 —— 表(biǎo)示葉輪名義直徑(mm) |

| 適用工況 |

1、泵(bèng)流量範圍:15~2500m3/h

2、揚程範圍: 5~60m

3、重量濃度:≤60%

4、介質(zhì)溫度:≤100℃

5、PH值:2.5~13 |

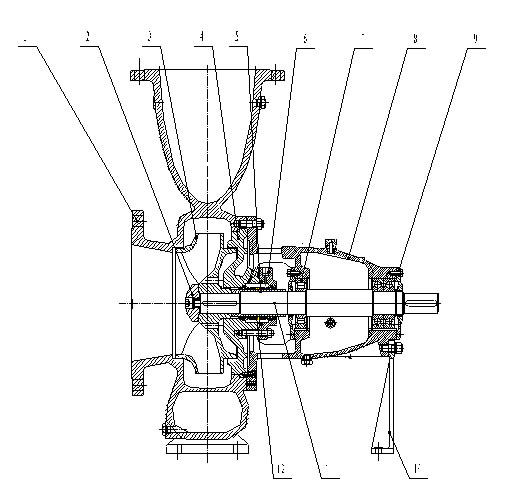

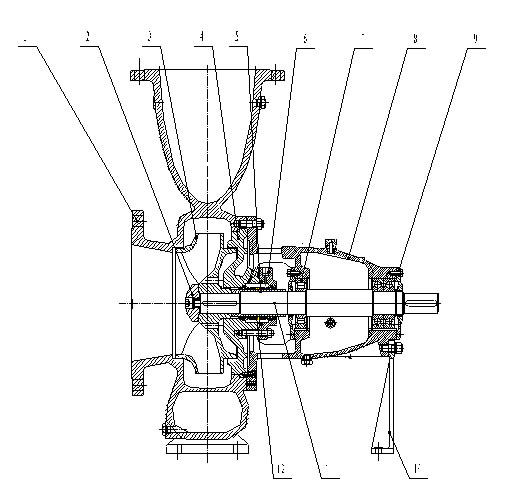

| 結構形(xíng)式 |

|

1、泵體(tǐ) 2、葉輪壓板 3、葉輪 4、泵蓋 5、軸套

6、機械密封壓蓋 7、軸承 8、懸架(jià)體 9、軸承壓(yā)蓋

10、支腳 11、軸 12、機械密封 |

| 性能參數(shù)表 |

型號(hào) |

流量m3/h |

揚程m |

轉(zhuǎn)速

r/min |

配用(yòng)

功率

KW |

汽蝕

餘量

m |

通過

顆粒

直徑 |

效率

η

% |

進(jìn)口

直徑

mm |

出口

直徑

mm |

額點 |

範圍 |

額點 |

範圍(wéi) |

XJ65-200 |

|

25 |

20-35 |

12.5 |

15-8 |

1450 |

3 |

1.8 |

20 |

61 |

100 |

65 |

A |

20 |

18-30 |

10 |

10-6 |

2.2 |

54 |

XJ65-250 |

|

25 |

20-35 |

20 |

23-18 |

4 |

56 |

A |

20 |

18-30 |

18 |

18-16 |

3 |

52 |

XJ65-320 |

|

25 |

20-35 |

32 |

36-23 |

7.5 |

53 |

A |

20 |

18-30 |

27 |

30-26 |

5.5 |

51 |

B |

16 |

16-25 |

25 |

26-23 |

4 |

50 |

XJ65-400 |

|

25 |

20-35 |

50 |

56-50 |

11 |

51 |

A |

20 |

18-30 |

46 |

48-45 |

7.5 |

50 |

B |

16 |

16-25 |

42 |

45-41 |

5.5 |

49 |

XJ80-200 |

|

50 |

35-75 |

12.5 |

15-8 |

1450 |

4 |

1.9 |

35 |

69 |

125 |

80 |

A |

45 |

30-65 |

10 |

10-6 |

3 |

68 |

B |

40 |

25-55 |

8 |

8-6 |

2.2 |

67 |

XJ80-250 |

|

50 |

35-75 |

20 |

23-16 |

7.5 |

65 |

A |

45 |

30-60 |

18 |

20-16 |

5.5 |

64 |

B |

40 |

25-55 |

16 |

18-16 |

5.5 |

63 |

XJ80-320 |

|

50 |

35-75 |

32 |

36-32 |

11 |

61 |

A |

45 |

30-65 |

27 |

30-26 |

11 |

60 |

B |

40 |

25-55 |

25 |

26-23 |

7.5 |

59 |

XJ80-400 |

|

50 |

35-75 |

50 |

56-50 |

18.5 |

59 |

A |

45 |

30-60 |

46 |

48-45 |

15 |

58 |

B |

40 |

25-55 |

42 |

45-41 |

11 |

57 |

XJ100-210 |

|

100 |

75-120 |

12.5 |

15-8 |

1450 |

7.5 |

2.1 |

35 |

74 |

125 |

100 |

A |

70 |

06-110 |

10 |

10-8 |

4 |

73 |

B |

65 |

50-90 |

8 |

8-6 |

3 |

72 |

XJ100-250 |

|

100 |

75-120 |

20 |

23-16 |

11 |

73 |

A |

70 |

60-110 |

18 |

20-18 |

7.5 |

72 |

B |

65 |

50-90 |

16 |

18-16 |

5.5 |

71 |

XJ100-300 |

|

100 |

75-120 |

32 |

36-32 |

18.5 |

71 |

A |

70 |

60-110 |

27 |

30-26 |

15 |

70 |

B |

65 |

50-90 |

25 |

26-23 |

11 |

69 |

XJ100-410 |

|

100 |

75-120 |

50 |

56-50 |

30 |

62 |

A |

70 |

60-110 |

46 |

48-45 |

22 |

61 |

B |

65 |

50-90 |

42 |

45-41 |

18.5 |

60 |

|

| 續表1 |

型(xíng)號 |

流量m3/h |

揚程m |

轉速

r/min |

配用

功率

KW |

汽蝕

餘量

m |

通過

顆粒

直(zhí)徑 |

效率

η

% |

進(jìn)口

直徑

mm |

出口

直徑

mm |

額點 |

範圍 |

額點 |

範圍 |

XJ125-220 |

|

150 |

120-175 |

12.5 |

15-8 |

1450 |

11 |

2.2 |

40 |

75 |

150 |

125 |

A |

120 |

100-160 |

10 |

10-8 |

7.5 |

74 |

B |

110 |

90-150 |

8 |

8-6 |

5.5 |

73 |

XJ125-270 |

|

150 |

120-200 |

20 |

23-16 |

18.5 |

75 |

A |

120 |

100-160 |

18 |

20-18 |

11 |

74 |

B |

110 |

90-150 |

16 |

18-16 |

7.5 |

73 |

XJ125-340 |

|

150 |

120-280 |

32 |

36-23 |

30 |

72 |

A |

120 |

100-250 |

27 |

30-26 |

22 |

71 |

B |

110 |

90-200 |

25 |

26-23 |

18.5 |

70 |

XJ125-410 |

|

150 |

120-280 |

50 |

56-50 |

45 |

67 |

A |

120 |

100-250 |

46 |

48-45 |

37 |

66 |

B |

110 |

90-200 |

42 |

45-41 |

30 |

65 |

XJ150-230 |

|

250 |

180-320 |

12.5 |

15-8 |

1450 |

15 |

2.6 |

55 |

76 |

200 |

150 |

A |

210 |

180-280 |

10 |

10-8 |

11 |

75 |

B |

180 |

160-260 |

8 |

8-6 |

7.5 |

74 |

XJ150-280 |

|

250 |

180-320 |

20 |

23-16 |

22 |

76 |

A |

210 |

180-280 |

18 |

20-18 |

18.5 |

75 |

B |

180 |

160-260 |

16 |

18-16 |

15 |

74 |

XJ150-340 |

|

250 |

180-320 |

32 |

36-23 |

37 |

76 |

A |

210 |

180-280 |

27 |

30-26 |

30 |

75 |

B |

180 |

160-260 |

25 |

26-23 |

22 |

74 |

XJ150-410 |

|

250 |

180-320 |

50 |

56-50 |

55 |

73 |

A |

210 |

180-280 |

46 |

48-45 |

45 |

72 |

B |

180 |

160-260 |

42 |

45-41 |

37 |

71 |

XJ200-240 |

|

400 |

320-550 |

12.5 |

15-8 |

1450 |

22 |

3.3 |

65 |

76 |

250 |

200 |

A |

370 |

370-450 |

10 |

10-8 |

18.5 |

75 |

B |

350 |

320-370 |

8 |

8-6 |

15 |

74 |

XJ200-290 |

|

400 |

320-550 |

20 |

23-16 |

37 |

78 |

A |

370 |

370-450 |

18 |

20-18 |

30 |

78 |

B |

350 |

320-370 |

16 |

18-16 |

22 |

77 |

XJ200-340 |

|

400 |

320-550 |

32 |

36-23 |

55 |

78 |

A |

370 |

370-450 |

27 |

30-25 |

45 |

77 |

B |

350 |

320-370 |

25 |

26-23 |

37 |

76 |

XJ200-430 |

|

400 |

320-550 |

50 |

56-50 |

90 |

76 |

A |

370 |

370-450 |

46 |

48-45 |

75 |

75 |

B |

350 |

320-370 |

42 |

45-41 |

55 |

74 |

XJ200-250 |

|

550 |

480-650 |

12.5 |

15-8 |

1450 |

30 |

4.0 |

70 |

77 |

250 |

200 |

A |

500 |

500-600 |

10 |

10-8 |

22 |

76 |

B |

480 |

480-500 |

8 |

8-6 |

18.5 |

75 |

|

| 續表3 |

型號 |

流量m3/h |

揚程m |

轉速(sù)

r/min |

配(pèi)用

功率

KW |

汽蝕

餘量

m |

通過

顆粒

直徑 |

效率

η

% |

進口

直(zhí)徑

mm |

出口(kǒu)

直徑(jìng)

mm |

額點(diǎn) |

範圍 |

額點 |

範圍 |

XJ350-600 |

|

1500 |

1350-1650 |

32 |

36-23 |

980 |

220 |

4.5 |

80 |

81 |

400 |

350 |

A |

1350 |

1350-1550 |

27 |

30-26 |

185 |

81 |

B |

1250 |

1250-1450 |

25 |

26-23 |

160 |

81 |

XJ350-650 |

|

1500 |

1350-1650 |

50 |

56-50 |

355 |

81 |

A |

1350 |

1350-1550 |

46 |

48-45 |

315 |

79 |

B |

1250 |

1250-1450 |

42 |

45-41 |

280 |

78 |

XJ400-450 |

|

1650 |

1600-18, 00 |

12.5 |

15-18 |

980 |

110 |

4.8 |

85 |

79 |

450 |

400 |

A |

1480 |

1400-1550 |

10 |

10-8 |

90 |

78 |

B |

1380 |

1300-1450 |

8 |

8-6 |

75 |

77 |

XJ400-500 |

|

1650 |

1600-1800 |

20 |

23-16 |

132 |

82 |

A |

1480 |

1400-1550 |

18 |

20-18 |

110 |

80 |

B |

1380 |

1300-1450 |

16 |

18-16 |

90 |

78 |

XJ400-550 |

|

1650 |

1600-1800 |

32 |

36-23 |

320 |

83 |

A |

1480 |

1400-1550 |

27 |

30-26 |

185 |

80 |

B |

1380 |

1300-1550 |

25 |

26-23 |

160 |

79 |

XJ400-600 |

|

1650 |

1600-1800 |

50 |

56-50 |

355 |

83 |

A |

1480 |

1400-1550 |

46 |

48-45 |

315 |

81 |

B |

1380 |

1300-1450 |

42 |

45-41 |

280 |

79 |

XJ450-500 |

|

2000 |

1850-2250 |

12.5 |

15-8 |

980 |

160 |

5 |

90 |

83 |

500 |

450 |

A |

1850 |

1800-2000 |

10 |

10-8 |

132 |

80 |

B |

1700 |

1650-1900 |

8 |

8-6 |

110 |

79 |

XJ450-550 |

|

2000 |

1850-2250 |

20 |

23-16 |

280 |

84 |

A |

1850 |

1800-2000 |

18 |

20-18 |

250 |

82 |

B |

1700 |

1650-1900 |

16 |

18-16 |

220 |

80 |

XJ450-600 |

|

2300 |

2100-2500 |

32 |

36-23 |

315 |

85 |

A |

2150 |

2000-2300 |

27 |

30-25 |

280 |

84 |

B |

1950 |

1900-2100 |

25 |

25-23 |

250 |

82 |

XJ450-650 |

|

2300 |

2100-2500 |

50 |

56-50 |

500 |

95 |

A |

2150 |

2000-2300 |

45 |

48-45 |

450 |

83 |

B |

1950 |

1900-2100 |

42 |

45-41 |

400 |

81 |

|

| 注:型號後麵帶"A"代表葉輪第一次切削後的性能參數,電機功率也隨之調整配置。B、C、D葉輪經第二、三、四次切削,本性能不一一列舉,用戶(hù)選型可在性能(néng)內選(xuǎn)擇即可。 |

| |

| |