| |

|

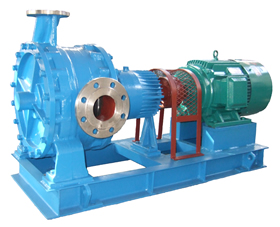

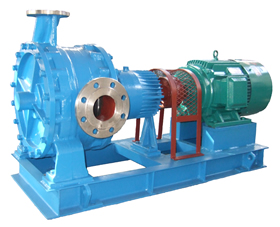

YLB壓濾機專用泵 |

| 流量範圍:6.3~200m3/h |

| 揚程範圍:5~125m |

| 介質(zhì)溫度:-10℃~110℃ |

| 輸送有顆粒、粘度的(de)各(gè)種腐蝕液體漿料 |

| |

谘詢熱線:13801427722 13952608395 谘詢熱線:13801427722 13952608395 |

|

| |

| 詳細介紹 |

| 概 述 |

YLB無泄漏壓濾機專用(yòng)泵是引進德國進口(kǒu)泵經本廠(chǎng)水泵設計按用戶實際使用要求精心設計、並研(yán)製成功的新型無泄漏壓濾機專用泵,YLB泵廣泛應用於化(huà)工、石(shí)油、澱粉、製藥(yào)、農藥、染料、油漆、冶煉、造紙、電鍍、電力、食物等多個行業。

YLB壓濾機專用泵是為輸送含(hán)顆粒性較大的漿料或有砂石之類的礦漿而設計的一種(zhǒng)低轉速大流(liú)道泵,其結(jié)構采用(yòng)軸向入口,徑向出口,確保較大(dà)的砂石顆粒進入泵(bèng)腔後通過(guò)開(kāi)式葉(yè)輪立刻(kè)甩出,不會因停留泵腔內而導致磨損或顆粒(lì)卡在(zài)葉輪與泵蓋、泵體之間。 |

| 優 點 |

產品材質(zhì)有氟塑料、超(chāo)高分子聚乙烯、增強聚丙烯、1Cr18Ni9Ti、1Cr18Ni12Mo2Ti、316、316L,SUS304、SUS304L,蒙(méng)乃樂(lè),哈氏合金,耐熱、耐(nài)腐合(hé)金等(děng)。

YLB壓濾機專用泵機(jī)械密封采用負壓裝置,在(zài)壓(yā)力(lì)不斷增加而流量逐漸減少的(de)情況下長(zhǎng)期輸送液體,機械密封不承受工作壓力(lì),確保機械密封永(yǒng)不泄(xiè)漏,是建設文明工廠的理想設備。

其額定性能點和(hé)尺寸等都采用國際尺度ISO2858-1975(E),是取代搪瓷泵、陶瓷泵、襯(chèn)膠泵、氟合金泵、F型耐(nài)腐泵、IH化(huà)工離心泵更新換(huàn)代產品,能滿足壓濾機工藝流程中輸送溫(wēn)度為-10℃~180℃帶有顆粒、粘(zhān)度的各種腐蝕液體漿料。 |

| 性能範圍 |

流量範圍(wéi)6.3~200m3/h,揚程(chéng)5~125m。

用戶(hù)可(kě)根據不同介質前提選用相應的密(mì)封結(jié)構,該(gāi)泵不僅能在壓濾機特殊前提下(xià)使用,同時能滿足各種工況前提下酸堿溶劑的輸送。 |

| 性能參數表 |

型號 |

流量Q |

揚程H |

最高壓力(lì) |

電機功率 |

轉速 |

m3/h |

m |

kg |

(kw) |

rpm |

YLB50-40-K |

12.5 |

40 |

4 |

5.5 |

2900 |

YLB50-50-K |

12.5 |

50 |

5 |

7.5 |

2900 |

YLB50-60-K |

12.5 |

60 |

6 |

11 |

2900 |

YLB50-70-K |

12.5 |

70 |

7 |

15 |

2900 |

YLB50-80-K |

12.5 |

80 |

8 |

15 |

2900 |

YLB50-100-K |

12.5 |

100 |

10 |

15 |

2900 |

YLB65-42-K |

25 |

42 |

4.2 |

11 |

2900 |

YLB65-50-K |

25 |

50 |

5 |

15 |

2900 |

YLB65-60-K |

25 |

60 |

6 |

18.5 |

2900 |

YLB65-70-K |

25 |

70 |

7 |

18.5 |

2900 |

YLB65-80-K |

25 |

80 |

8 |

22 |

2900 |

YLB65-100-K |

25 |

100 |

10 |

22 |

2900 |

YLB80-40-K |

50 |

40 |

4 |

15 |

2900 |

YLB80-50-K |

50 |

50 |

5 |

18.5 |

2900 |

YLB80-60-K |

50 |

60 |

6 |

22 |

2900 |

YLB80-70-K |

50 |

70 |

7 |

30 |

2900 |

YLB80-80-K |

50 |

80 |

8 |

37 |

2900 |

YLB80-100-K |

50 |

100 |

10 |

37 |

2900 |

YLB100-40-K |

100 |

40 |

4 |

22 |

2900 |

YLB100-50-K |

100 |

50 |

5 |

30 |

2900 |

YLB100-60-K |

100 |

60 |

6 |

37 |

2900 |

YLB100-70-K |

100 |

70 |

7 |

45 |

2900 |

YLB100-80-K |

100 |

80 |

8 |

45 |

2900 |

YLB100-100-K |

100 |

100 |

10 |

45 |

2900 |

YLB125-20-K |

200 |

20 |

2 |

30 |

2900 |

YLB125-30-K |

200 |

30 |

3 |

37 |

2900 |

YLB125-40-K |

200 |

40 |

4 |

45 |

2900 |

YLB125-50-K |

200 |

50 |

5 |

55 |

2900 |

YLB125-60-K |

200 |

60 |

6 |

75 |

2900 |

YLB125-70-K |

200 |

70 |

7 |

90 |

2900 |

YLB125-80-K |

200 |

80 |

8 |

110 |

2900 |

YLB50-40-D-K |

12.5 |

40 |

4 |

11 |

1450 |

YLB50-50-D-K |

12.5 |

50 |

5 |

15 |

1450 |

YLB50-60-D-K |

12.5 |

60 |

6 |

15 |

1450 |

YLB50-70-D-K |

12.5 |

70 |

7 |

18.5 |

1450 |

YLB50-80-D-K |

12.5 |

80 |

8 |

22 |

1450 |

YLB50-100-D-K |

12.5 |

100 |

6 |

18.5 |

1450 |

YLB65-42-D-K |

25 |

42 |

4.2 |

11 |

1450 |

YLB65-50-D-K |

25 |

50 |

5 |

15 |

1450 |

YLB65-60-D-K |

25 |

60 |

6 |

18.5 |

1450 |

YLB65-70-D-K |

25 |

70 |

7 |

18.5 |

1450 |

YLB65-80-D-K |

25 |

80 |

8 |

22 |

1450 |

YLB65-100-D-K |

25 |

100 |

10 |

22 |

1450 |

YLB80-40-D-K |

50 |

40 |

4 |

15 |

1450 |

YLB80-50-D-K |

50 |

50 |

5 |

18.5 |

1450 |

YLB80-60-D-K |

50 |

60 |

6 |

22 |

1450 |

YLB80-70-D-K |

50 |

70 |

7 |

30 |

1450 |

YLB80-80-D-K |

50 |

80 |

8 |

37 |

1450 |

YLB80-100-D-K |

50 |

100 |

10 |

37 |

1450 |

YLB100-40-D-K |

100 |

40 |

4 |

15 |

1450 |

YLB100-50-D-K |

100 |

50 |

5 |

18.5 |

1450 |

YLB100-60-D-K |

100 |

60 |

6 |

22 |

1450 |

YLB100-70-D-K |

100 |

70 |

7 |

30 |

1450 |

YLB100-80-D-K |

100 |

80 |

8 |

37 |

1450 |

YLB100-100-D-K |

100 |

100 |

10 |

45 |

1450 |

YLB125-20-D-K |

100 |

20 |

2 |

11 |

1450 |

YLB125-30-D-K |

100 |

30 |

3 |

15 |

1450 |

YLB125-40-D-K |

100 |

40 |

4 |

18.5 |

1450 |

YLB125-50-D-K |

150 |

50 |

5 |

37 |

1450 |

YLB125-60-D-K |

150 |

60 |

6 |

45 |

1450 |

YLB125-70-D-K |

150 |

70 |

7 |

55 |

1450 |

YLB125-80-D-K |

150 |

80 |

8 |

75 |

1450 |

|

| |

| |